Ultimate Guide to Final Drive Parts for Auto and Motorcycle Equipment

In the competitive and ever-evolving world of auto parts & supplies and motorcycle parts & supplies, maintaining optimal performance and durability of machinery is paramount. Among the critical components that ensure smooth operation and efficient power transfer is the final drive. Understanding the nuances of final drive parts, their significance, and how to choose the right components can significantly enhance your equipment's lifespan and operational efficiency. Visit our full range of final drive parts here.

What is a Final Drive and Why is it Vital for Auto & Motorcycle Machinery?

The final drive is a crucial component within the drivetrain system of various vehicles and heavy machinery. It is responsible for transmitting power from the transmission to the wheels or tracks, effectively converting rotational motion into the movement of the vehicle. Whether you're working with compact construction equipment, heavy-duty excavators, or motorcycles, the final drive ensures that torque is delivered efficiently and reliably.

High-quality final drive parts are essential not only for optimal performance but also for safety and longevity of your equipment. A malfunction or failure in this component can lead to costly downtimes and repairs, making awareness and regular maintenance vital for operators and business owners alike.

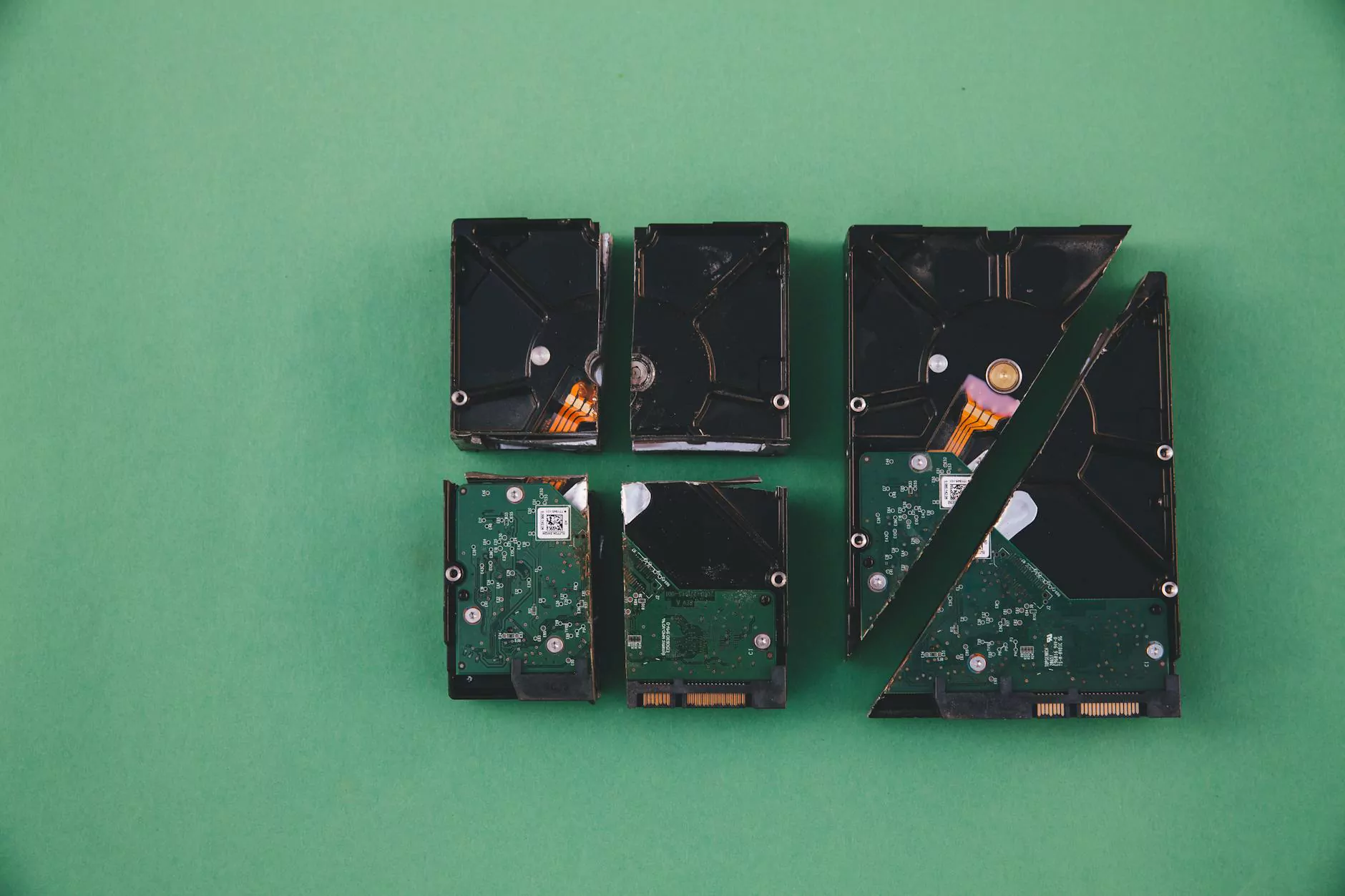

Key Components Within the Final Drive System

The final drive encompasses multiple critical parts, each playing a significant role:

- Final drive gear assembly: Transfers torque from the power source to the wheels/tracks.

- Ring gear: Engages with the drive pinion to transfer rotational motion.

- Drive pinion: Connects to the power source, initiating the gear rotation.

- Hydraulic motor (for certain machinery): Converts hydraulic pressure into rotational energy for the drive system.

- Bearings and seals: Ensure smooth operation and prevent contaminants from entering.

- Final drive housing: Protects the internal components and maintains structural integrity.

Choosing the Right Final Drive Parts for Your Equipment

Selecting the correct final drive components is crucial for maintaining the performance, efficiency, and safety of your machinery. At Shop Hydraulic America, we offer an extensive range of final drive parts tailored for various makes and models of autos and motorcycles. Here's what to consider when choosing replacement parts:

Compatibility and Specifications

Ensure that the final drive parts are compatible with your specific equipment. Refer to the user manual or consult with our experts to identify the right specifications, including gear ratios, mounting configurations, and capacity ratings.

Material Quality and Durability

Opt for components manufactured from high-grade, wear-resistant materials such as hardened steel or alloy steel. This ensures longevity and resistance to harsh operating conditions.

OEM vs. Aftermarket Parts

While Original Equipment Manufacturer (OEM) parts guarantee exact fit and performance, high-quality aftermarket options can offer cost-effective alternatives without compromising quality. Shop Hydraulic America provides both options, backed by rigorous quality standards.

Comprehensive Benefits of Using Premium Final Drive Parts

Investing in the right final drive parts brings numerous advantages, including:

- Enhanced Performance: Ensures smooth power transmission and prevents mechanical lag.

- Extended Equipment Lifespan: Reduces wear and tear, leading to fewer repairs and replacements.

- Increased Operational Efficiency: Optimizes fuel consumption and productivity.

- Lower Maintenance Costs: High-quality components resist damage and corrosion, reducing routine maintenance efforts.

- Safety and Reliability: Minimizes unexpected failures that could jeopardize operator safety.

Maintenance Tips for Final Drive Components

To preserve the integrity and performance of your final drive parts, regular maintenance is recommended. Here are some essential tips:

- Routine Inspection: Regularly check for signs of wear, leaks, or damage.

- Lubrication: Keep gear oils and lubricants at the recommended levels and replace them periodically to prevent friction and overheating.

- Cleaning: Remove dirt, debris, and contaminants that could accelerate wear.

- Seal Checks: Ensure that seals are intact to prevent contamination and fluid leaks.

- Prompt Replacement: Replace worn or damaged parts immediately to prevent collateral damage to other components.

Why Shop Hydraulic America is Your Best Choice for Final Drive Parts

Shop Hydraulic America has established itself as a trusted source for high-quality final drive components in the industry. Our commitment to excellence and customer satisfaction is reflected in our extensive inventory, competitive pricing, and expert support. We cater to a wide range of machinery—from compact excavators and bulldozers to motorcycles and other power sports equipment.

Some of the key reasons to choose us include:

- Wide Selection: Access to a comprehensive catalog of final drive gears, rings, pins, and related components.

- Quality Assurance: All parts undergo rigorous testing to meet or exceed industry standards.

- Expert Advice: Our team of specialists is available to guide you through the selection process and answer technical questions.

- Fast Shipping: Prompt delivery ensures minimal downtime for your projects.

- Competitive Pricing: Affordable options without compromising on quality.

Operational Efficiency and Cost Savings with Proper Final Drive Maintenance

Proper maintenance and timely replacement of final drive parts are not only crucial for safety but also lead to significant cost savings. When your machinery operates at peak efficiency, fuel consumption decreases, and the risk of unexpected breakdowns diminishes, saving you money and reducing project delays.

Furthermore, investing in durable, high-quality parts reduces the frequency of repairs, thus avoiding the cumulative costs associated with frequent replacements and downtime. Regular inspections, combined with quality replacements from Shop Hydraulic America, ensure your machinery runs smoothly day after day.

Final Drive Replacement and Repair Services

While preventative maintenance extends the life of your final drive parts, sometimes replacements become inevitable due to wear or damage. Our expert team can assist in diagnosing issues, recommending appropriate parts, and providing professional repair services to restore your equipment to optimal condition.

Conclusion: Maximize Your Machinery’s Performance with the Right Final Drive Parts

Investing in high-quality final drive components is a strategic decision that impacts the long-term performance, safety, and profitability of your machinery. Whether you're managing a construction fleet, maintaining a motorcycle fleet, or operating heavy-duty equipment, choosing the right parts and adhering to proper maintenance protocols are essential.

At Shop Hydraulic America, we stand ready to support your needs with an extensive selection of durable, reliable final drive parts accompanied by expert guidance. Take control of your equipment’s performance today and experience the difference that premium components make.

Explore our full catalog of final drive parts now and ensure your machinery continues to deliver top-tier performance for years to come.

https://shophydraulicamerica.com/final-drive/